Mining Topic: Maintainability

What is the health and safety problem?

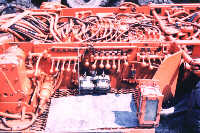

Although equipment manufacturers have made progress in enhancing maintainability, new advances of technology have made equipment more complex. These advances require more from the workers who maintain mining equipment, and additional training in maintaining complex systems is becoming more critical to workers performing their tasks safely.

What is the extent of the problem?

Maintenance activities on machinery account for about 30% of the injuries/fatalities in the underground coal mining industry. Stakeholders have recently voiced concerns over these types of accidents and expressed their desire to see investigations and efforts into reducing maintenance-related injuries.

How is the NIOSH Mining program addressing this problem?

Complex machines can hinder maintainability.

The Office of Mine Safety and Health Research (OMSHR) has been addressing maintainability issues by conducting numerous studies over the years that focus on machine design for maintenance. These issues include development of maintainability checklists, efforts to stress training and work procedures, examinations of the work environment, equipment, tools, and personal protective equipment.

What are the significant findings?

Results to decrease the frequency and severity of injuries to mine workers while performing maintenance activities have stressed mine worker training and work procedures, improved work environments and safety and environmental control equipment, improved personal protective equipment, improved equipment control and display design, enhanced lighting and visibility-related research, and organizational issues.

What are the next steps?

Future maintenance safety research by OMSHR will not only address issues and hazards that have been linked to many past injuries associated with equipment maintenance but will also address potential hazards from new technology. Examples will include research into lock-out/tag-out procedures and new technology that will improve monitoring and procedure compliance, as well as improved maintenance procedures and equipment design recommendations.

- Analysis of Fatalities During Maintenance and Repair Operations in the U.S. Mining Sector

- Design of Surface Mine Haulage Roads - a Manual

- Development and Evaluation of a Training Exercise for Construction, Maintenance and Repair Work Activities

- Development of Ergonomics Audits for Bagging, Haul Truck and Maintenance and Repair Operations in Mining

- ErgoMine - 2.1

- Fall From Equipment Injuries in U.S. Mining: Identification of Specific Research Areas for Future Investigation

- Hazard Recognition Training Program for Construction, Maintenance and Repair Activities

- Impact of Maintainability Design on Injury Rates and Maintenance Costs for Underground Mining Equipment

- Machine-Related Injuries in the US Mining Industry and Priorities for Safety Research

- Maintainability Design Checklist

- The Potential Impact of Light Emitting Diode Lighting on Reducing Mining Injuries During Operation and Maintenance of Lighting Systems

- Reducing Machine Guarding-Related Injuries in Mining

- Seating Design Principles

- Systems Approach to Design

- Technology News 554 - ErgoMine Targets Ergonomics and Safety Issues in Mining