Hazard Communication for Disinfectants Used Against Viruses

Health Hazards and Protective Measures

Overview

This information is intended to be used by employers and workers who use cleaning products and disinfectants, specifically those identified as effective against viruses, including avian (bird) flu, Ebola, and SARS-CoV-2 (the virus that causes COVID-19).

This page offers information about the health hazards that could be caused by cleaning products and disinfectants and the recommended barrier and respiratory protection workers can use to protect themselves from these hazards. When using disinfectants, the proper barrier protection should be used. This information, focusing on worker safety, supplements existing Centers for Disease Control and Prevention (CDC) guidance for disinfection of viruses.

Both cleaning and disinfecting are important for reducing the spread of viral illnesses. Some viruses may remain viable (living) for hours to days on surfaces made from a variety of materials. Cleaning surfaces followed by disinfection is a best practice for preventing the spread of viral illnesses in the workplace. Cleaning refers to the removal of germs, dirt, and impurities from surfaces. Cleaning does not kill germs, but by removing them, it lowers their numbers and the risk of spreading infection. Disinfecting refers to using chemicals to kill germs on surfaces. Disinfecting does not necessarily clean dirty surfaces or remove germs, but by killing germs that remain on a surface after cleaning, disinfecting can further lower the risk of spreading infection.

Considerations regarding the use of disinfectants

Many chemical disinfectants can be harmful to workers if they are unsafely handled and/or improperly used. Therefore, it is important that disinfectants are selected and used properly to ensure effective disinfection and avoid harm to individuals and damage to surfaces. Proper use of disinfectants should include:

- Selecting the appropriate disinfectant based on the type of surface to be disinfected (e.g., hard surface, soft surface, electronics, fabric, etc.)

- Understanding all potential health hazards and using all recommended protective measures, including barriers to prevent contact with body parts and respiratory protection (see table below)

- Following manufacturers’ instructions and product label directions for safe, effective use

- Using the proper concentration and application method

- Making sure to follow the required contact time (i.e., the amount of time the surface should be visibly wet) following application

- NEVER mix disinfectants with cleaners, other disinfectants, or other chemicals

- Mixing some chemical disinfectants with other chemical substances could be hazardous. For example, the toxic gas chlorine can be released if you mix sodium hypochlorite (bleaching solutions) and acidic cleaning agents.

- Mixing a disinfectant with anything else could change its properties and it may no longer be effective.

Health hazards and protective measures for chemicals used as disinfectants

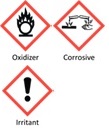

The table below provides information about health hazards associated with recommended disinfectants for use against viruses and suggestions for how individuals can protect themselves against those health hazards while using the products. The table includes the following information:

- The chemical name and common names for that chemical

- The chemical abstract service number (CAS No.)

- Globally Harmonized System of Classification and Labelling of Chemicals (GHS) pictograms

- Health and flammability-related hazard statements

- Recommended glove barriers

- Recommended respiratory protection (commonly known as personal protective equipment).

The GHS pictograms and hazard statements for each chemical were obtained from the International Chemical Safety Cards (ICSCs). If the ICSC did not have this information available for a chemical, the GESTIS database from the Institute for Occupational Safety and Health of the German Social Accident Insurance was used to identify this information. If neither GHS pictograms or hazard statements were available from these resources, then data from the European Chemicals Agency (ECHA) substance infocards were used to supplement the chemical information.

The table does not include an exhaustive list of all barriers for each chemical. The recommended barriers included in the table are from the Quick Selection Guide to Chemical Protective Clothing.[1] Glove material is often referred to by the generic materials, including butyl rubber, natural rubber, neoprene rubber, nitrile rubber, and polyvinylchloride (PVC). Some barriers may offer better protection for a variety of chemicals than other barriers, and thicknesses of the barrier materials can vary from manufacturer to manufacturer [1]. Selection recommendations are based on data from permeation and degradation under laboratory conditions. The most common ways chemicals pass through a protective barrier include 1) penetration, such as a tear or rip, 2) permeation, where the chemical diffuses through the barrier, and 3) degradation, which is the break-down of the protective material. Permeation breakthrough time is the time that it takes a chemical to diffuse through a barrier at a specific permeation rate [1]. The barriers included for each chemical are categorized by reported resistance to chemical breakthrough of greater than four hours (>4 hours) or greater than eight hours (>8 hours) under conditions of continuous contact with the chemical. “Greater than 8 hours” does not mean there was not permeation; this means that permeation did not exceed 1.0 µg/cm2/min during the 8-hour test. More information, including more glove barrier options, is available in the Quick Selection Guide to Chemical Protective Clothing.[1] Personal protective equipment (PPE) manufacturers may also provide additional information regarding PPE products.

The recommended respiratory protection for a chemical is typically listed in the manufacturer’s safety data sheet and many chemicals have respirator recommendations in the NIOSH Pocket Guide to Chemical Hazards. Respirators protect the user in two basic ways. The first is by the removal of contaminants from the air, which includes particle respirators and “gas masks.” Other respirators, like airline respirators and self-contained breathing apparatus (SCBA), protect by supplying clean respirable air from another source. Respirators should only be used when engineering or administrative control systems are not feasible or fully effective. Engineering control systems, such as adequate ventilation or scrubbing of contaminants, are the preferred control methods for reducing worker exposures. Proper use of respiratory protection (respirators) requires a comprehensive written respiratory protection program by the employer, and is described in Occupational Health and Safety Standards 29 CFR 1910.134.

Health and flammability hazards and barrier recommendations for common active ingredients in disinfectants

| Chemical (concentration) Other names* | CAS No. | GHS Pictogram(s) | Health and Flammability-related Hazard Statements | Recommended Glove Barriers § | Recommended Respiratory Protection** |

|---|---|---|---|---|---|

| Acetic acid † Ethanoic acid |

64-19-7 |  |

|

>8 hours: Butyl rubber |

Follow manufacturer’s recommendations in the product safety data sheet. NIOSH Pocket Guide to Chemical Hazards respirator guidance for acetic acid. |

| Calcium hypochlorite β Bleaching powder |

7778-54-3 |  |

|

No barrier guidance is provided in Forsberg (2020). Follow manufacturer’s recommendations on the product safety data sheet. | Follow manufacturer’s recommendations in the product safety data sheet. |

| Chlorine dioxide solution β Chlorine peroxide |

10049-04-4 |  |

|

No barrier guidance is provided for chlorine dioxide (liquid) in Forsberg (2020). Follow manufacturer’s recommendations on the product safety data sheet. | Follow manufacturer’s recommendations in the product safety data sheet. NIOSH Pocket Guide to Chemical Hazards respirator guidance for chlorine dioxide. |

| Citric acid β, §§ | 77-92-9 |  |

|

>8 hours: Butyl rubber Natural rubber Neoprene rubber Nitrile rubber Polyvinyl chloride |

Follow manufacturer’s recommendations in the product safety data sheet. |

| Didecyl dimethyl ammonium chloride (Quaternary ammonium compound) β | 7173-51-5 |  |

|

No barrier guidance is provided in Forsberg (2020). Follow manufacturer’s recommendations on the product safety data sheet. | Follow manufacturer’s recommendations in the product safety data sheet. |

| Dodecylbenzenesulfonic acid β | 27176-87-0 |  |

|

>8 hours: Butyl rubber Natural rubber Neoprene rubber Nitrile rubber |

Follow manufacturer’s recommendations in the product safety data sheet. |

| Ethyl alcohol † Ethanol |

64-17-5 |  |

|

>8 hours: Butyl rubber >4 hours: Neoprene rubber |

Follow manufacturer’s recommendations in the product safety data sheet. NIOSH Pocket Guide to Chemical Hazards respirator guidance for ethyl alcohol. |

| Formaldehyde†, ††, §§

|

50-00-0 |  |

|

>8 hours: Butyl rubber Nitrile rubber >4 hours: Neoprene rubber |

Follow manufacturer’s recommendations in the product safety data sheet. NIOSH Pocket Guide to Chemical Hazards respirator guidance for formaldehyde. |

| Glutaraldehyde (50% solution) †, §§ Glutaral |

111-30-8 |

|

|

>8 hours: Butyl rubber Neoprene rubber >4 hours: Nitrile rubber Polyvinyl chloride |

Follow manufacturer’s recommendations in the product safety data sheet. |

| Glycolic acid β Hydroxyacetic acid |

79-14-1 |  |

|

>8 hours: Butyl rubber Natural rubber Neoprene rubber Nitrile rubber Polyvinyl chloride |

Follow manufacturer’s recommendations in the product safety data sheet. |

| 1,2-Hexanediol β DL-hexane-1,2-diol |

6920-22-5 |  |

|

No barrier guidance is provided in Forsberg (2020). Follow manufacturer’s recommendations on the product safety data sheet. | Follow manufacturer’s recommendations in the product safety data sheet. |

| Hydrochloric acid solution β,§§ Hydrogen chloride |

7647-01-0 (anhydrous) |  |

|

>8 hours: Butyl rubber Neoprene rubber >4 hours: Natural rubber Nitrile rubber Polyvinylchloride – PVC |

Follow manufacturer’s recommendations in the product safety data sheet. NIOSH Pocket Guide to Chemical Hazards respirator guidance for Hydrochloric acid. |

| Hydrogen peroxide (>60% solution in water) †, §§ | 7722-84-1 |  |

|

>8 hours: Butyl rubber Natural rubber Neoprene rubber Nitrile rubber Polyvinylchloride – PVC |

Follow manufacturer’s recommendations in the product safety data sheet. NIOSH Pocket Guide to Chemical Hazards respirator guidance for hydrogen peroxide. |

| Isopropyl alcohol † Isopropanol Propan-2-ol |

67-63-0 |  |

|

>8 hours: Butyl rubber Neoprene rubber Nitrile rubber |

Follow manufacturer’s recommendations in the product safety data sheet. NIOSH Pocket Guide to Chemical Hazards respirator guidance for isopropyl alcohol. |

| Lactic acid β 2-hydroxypropanoic acid DL-Lactic acid |

50-21-5 |  |

|

>8 hours: Butyl rubber Natural rubber Neoprene rubber Nitrile rubber Polyvinylchloride – PVC |

Follow manufacturer’s recommendations in the product safety data sheet. |

| Octanoic acid β Caprylic acid |

124-07-2 |  |

|

>8 hours: Neoprene rubber Nitrile rubber |

Follow manufacturer’s recommendations in the product safety data sheet. |

| ortho-Phthalaldehyde †, §§ OPA |

643-79-8 |  |

|

>8 hours: Butyl rubber Neoprene rubber Nitrile rubber |

Follow manufacturer’s recommendations in the product safety data sheet. |

| ortho-Phenylphenol † 2-phenylphenol 2-Biphenylol 2-Hydroxybiphenyl |

90-43-7 |  |

|

No barrier guidance is provided in Forsberg (2020). Follow manufacturer’s recommendations on the product safety data sheet. | Follow manufacturer’s recommendations in the product safety data sheet. |

| ortho-Benzyl-para-chlorophenol β Clorofene |

120-32-1 |  |

|

No barrier guidance is provided in Forsberg (2020). Follow manufacturer’s recommendations on the product safety data sheet. | Follow manufacturer’s recommendations in the product safety data sheet. |

| Peracetic acid † PAA Peroxyacetic acid |

79-21-0 |  |

|

>8 hours: Butyl rubber >4 hours: Neoprene rubber |

Follow manufacturer’s recommendations in the product safety data sheet. |

| Phenol †, §§ Carbolic acid Hydroxybenzene phenic acid |

108-95-2 |  |

|

>8 hours: Butyl rubber >4 hours: Neoprene rubber |

Follow manufacturer’s recommendations in the product safety data sheet. NIOSH Pocket Guide to Chemical Hazards respirator guidance for phenol. |

| Potassium Peroxymonosulfate β Pentapotassium bis(peroxymonosulphate) bis(sulphate) |

70693-62-8 |  |

|

No barrier guidance is provided in Forsberg (2020). Follow manufacturer’s recommendations on the product safety data sheet. | Follow manufacturer’s recommendations in the product safety data sheet. |

| Sodium chlorite β Chlorous acid |

7758-19-2 |  |

|

No barrier guidance is provided in Forsberg (2020). Follow manufacturer’s recommendations on the product safety data sheet. | Follow manufacturer’s recommendations in the product safety data sheet. |

| Sodium dichloroisocyanurate β Troclosene sodium Sodium dichloro-S-triazinetrione |

2893-78-9 |  |

|

No barrier guidance is provided in Forsberg (2020). Follow manufacturer’s recommendations on the product safety data sheet. | Follow manufacturer’s recommendations in the product safety data sheet. |

| Sodium hydroxide †, §§ | 1310-73-2 |  |

|

>8 hours: Butyl rubber Natural rubber Neoprene rubber Nitrile rubber Polyvinyl chloride |

Follow manufacturer’s recommendations in the product safety data sheet. NIOSH Pocket Guide to Chemical Hazards respirator guidance for Sodium hydroxide. |

| Sodium hypochlorite (solution, active chlorine >10%) †, §§ Bleach |

7681-52-9 |  |

|

>8 hours: Butyl rubber Natural rubber Neoprene rubber Nitrile rubber Polyvinyl chloride |

Follow manufacturer’s recommendations in the product safety data sheet. |

| Thymol β 2-Isopropyl-5-methylphenol |

89-83-8 |  |

|

No barrier guidance is provided in Forsberg (2020). Follow manufacturer’s recommendations on the product safety data sheet. | Follow manufacturer’s recommendations in the product safety data sheet. |

| Triethylene glycol†, β, ββ 2,2′-(1,2-Ethanediyl bis (oxy))-bisethanol 2,2′-Ethylenedioxybis(ethanol) Triglycol |

112-27-6 | No classification |

|

No barrier guidance is provided in Forsberg (2020). Follow manufacturer’s recommendations on the product safety data sheet. | Follow manufacturer’s recommendations in the product safety data sheet. |

* In some cases, precautionary labels for the chemicals listed in the table may be more or less restrictive depending on the concentration of the chemical or other inert chemicals in the formulation of the disinfectant. Always review the label on the product before use. For chemicals or products not listed in the table above, follow manufacturers’ recommendations in the product’s safety data sheet.

† The pictograms and health hazards were obtained from the International Chemical Safety Cards (ICSCs) For more information about the pictograms please visit the OSHA website.

β The pictograms and health hazards were obtained from the Institute for Occupational Safety and Health of the German Social Accident Insurance GESTIS database.

§ Glove barrier recommendations are from the Quick Selection Guide to Chemical Protective Clothing.[1] Additional information on chemical protective clothing can be found in this resource. Always review the label on the product before use and follow manufacturers’ recommendations in the product’s safety data sheet.

** Additional information on respiratory protection recommendations, where available, can be found in the NIOSH Pocket Guide to Chemical Hazards in the links provided in the table.

†† OSHA standard 29 CFR 1910.1048 lists additional requirements for use of formaldehyde.

ββ The GHS pictograms and health hazards were obtained from the European Chemicals Agency (ECHA) substance infocards.

§§ Selection recommendations from the Quick Selection Guide to Chemical Protective Clothing [1] are based on concentrations of 30-70% (citric acid, formaldehyde, glutaraldehyde, hydrogen peroxide, ortho-Phthaldehyde, sodium hydroxide, and sodium hypochlorite), >70% (phenol), and 37% (hydrochloric acid).

The Occupational Safety and Health Administration (OSHA) Hazard Communication Standard, also known as the “Right to Know Law” [29 CFR 1910.1200], requires that employees are informed of potential work hazards and trained on associated safe practices, procedures, and protective measures. Employers must ensure employees have access to cleaning products’ safety data sheets (SDSs) and are informed of potential hazards and trained on the associated safe practices per the information found in the SDSs. Additionally, the 2008 Healthcare Infection Control Practices Advisory Committee (HICPAC) Guideline recommends each worker be informed of the possible health effect(s) of exposures to chemicals. This information should be consistent with SDSs, EPA regulations, and OSHA requirements and identify areas and tasks where there is the potential for exposure.

Additional resources

- OSHA/NIOSH InfoSheet: Protecting Workers Who Use Cleaning Chemicals

- Protect yourself: Cleaning Chemicals and Your Health

- Morbidity and Mortality Weekly Report (MMWR): Cleaning and Disinfectant Chemical Exposures and Temporal Associations with COVID-19 — National Poison Data System, United States, January 1, 2020–March 31, 2020

References

- Forsberg K, Van den Borre A, Henry III N, Zeigler JP. Quick Selection Guide to Chemical Protective Clothing, 7th Edition. Wiley. 2020.